| Availability: | |

|---|---|

● Industry standard currents of 16A or 21A

● With long expectancy, reliability

● Variety of levers, terminals and operating forces

● Heat resistant available

● RoHS compliant

ORDERING INFORMATION

NV- □ □ □ □ □ □

① ② ③ ④ ⑤ ⑥

1. Ratings | 2. Contact Gap | 3. Actuator |

21: 21A at 250VAC | None: 1mm | None: Pin plunger |

16: 16A at 250VAC | Z: Hinge lever | |

W: Simulated roller lever | ||

G: Hinge roller lever | ||

4. Contact Form | 5. Terminals | 6. Maximum Operating Force |

None: SPDT | A: Solder terminals | 6: 3.92N |

2: SPST-NC | C: Quick-connect terminal (#250) | 5: 1.96N |

3: SPST-NO | C2: Quick-cinnect terminal (#187) | 4: 0.98N |

RATINGS (REFERENCE VALUES)

Model | Reted voltage | No-inductive load | Inductive load | ||||||

Resistive load | Lamp load | Inductive load | Motor load | ||||||

NC | NO | NC | NO | NC | NO | NC | NO | ||

NV-21 | AC250V | 21A | 3A | 12A | 6A | ||||

DC8V | 21A | 5A | 12A | 7A | |||||

DC30V | 14A | 5A | 12A | 5A | |||||

DC125V | 0.6A | 0.1A | 0.6A | 0.1A | |||||

DC250V | 0.3A | 0.05A | 0.3A | 0.05A | |||||

NV-16 | AC250V | 16A | 2A | 10A | 6A | ||||

DC8V | 16A | 4A | 10A | 7A | |||||

DC30V | 10A | 4A | 10A | 5A | |||||

DC125V | 0.6A | 0.1A | 0.6A | 0.1A | |||||

DC250V | 0.3A | 0.05A | 0.3A | 0.05A | |||||

CONTACT SPECIFICATION

Item Type | NV-21Z2 / NV-16Z2 | ||

Allowable operating speed | 0.1mm~1m/s | ||

Operatingfrequency | Mechanical | 600 times/min | |

Electrical | 30 times/min | ||

Insulation resistance | Min.:100MΩ (above DC500C) | ||

Contact resistance | Max.:30mΩ initial value | ||

Dielectricstrength | BTW same polarity terminals | AC1000V 50/60Hz 1min | |

BTW current-carrying parts | AC1500V 50/60Hz 1min | ||

BTW terminal & metal parts | AC1500V 50/60Hz 1min | ||

Vibrationresistance | Malfunction | 10~55Hz double amplitude 1.5mm | |

Shockresistance | Durable | 1,000 m/s2 (approx. 100G) max. | |

Malfunction | 300 m/s2 (approx. 30G) max | ||

Expected lifelife | Mechanical life | 1x10 6 (60 operations/minute) | |

Electrical life | 1x10 5 (30 operations/minute) | ||

Protection degree | IEC IP40 | ||

Ambient operation temperature | -20℃~+125℃ | ||

Ambient humidity | 60%RH | ||

Contact material | silver alloy | ||

Weight | Approx. 6.2 g (plunger models) | ||

TECHNICAL DATA

Item | NV-21Z2 | NV-16Z2 | ||

Specification | Rivet | |||

Material | Silver alloy | |||

Gap (Standard value) | 0.5mm | |||

Inrushcurrent | NC | 50A max | 40A max | |

NO | ||||

Minimum applicable load | 160mA at 5VDC | |||

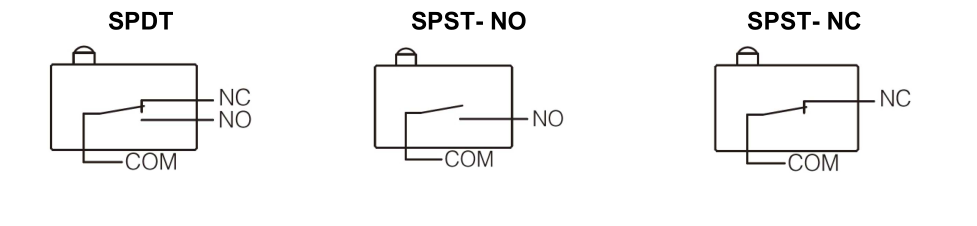

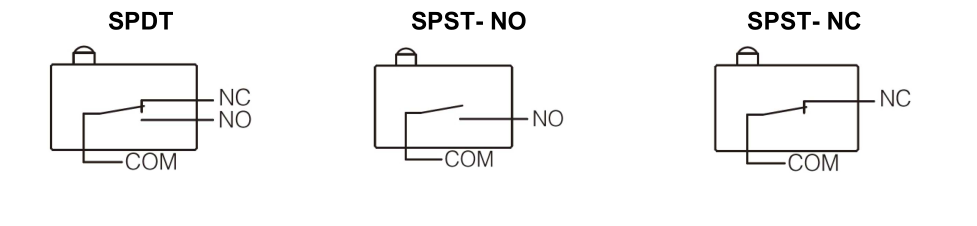

CONTACT FORM

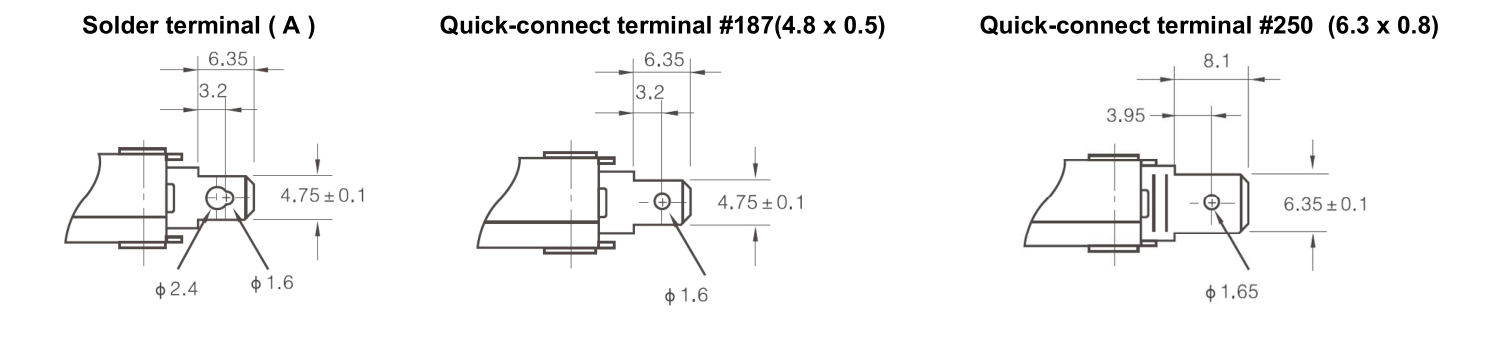

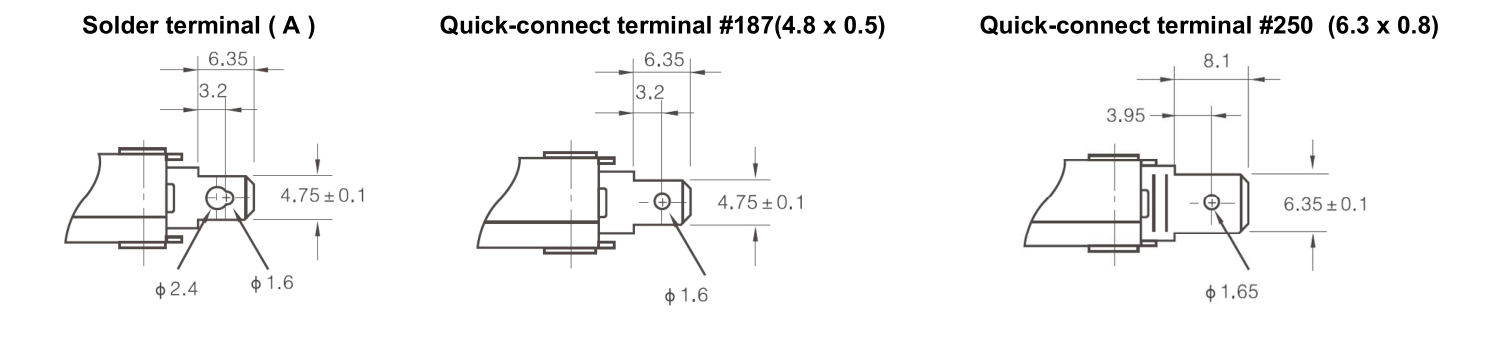

TERMINAL

SAFETY APPROVAL

UL61058

CSA-C22.2 No.61058-1

Ratedvoltage | NV-21 | NV-16 |

AC125V | 21A | 16A |

AC250V |

ENEC

(EN61058-1)

Ratedvoltage | NV-21 | NV-16 |

AC125V | 21A | 16A |

AC250V |

CQC

(GB15092.1)

Rated voltage | NV-21 | NV-16 |

AC125V | 21(6)A | 16(4)A |

AC250V |

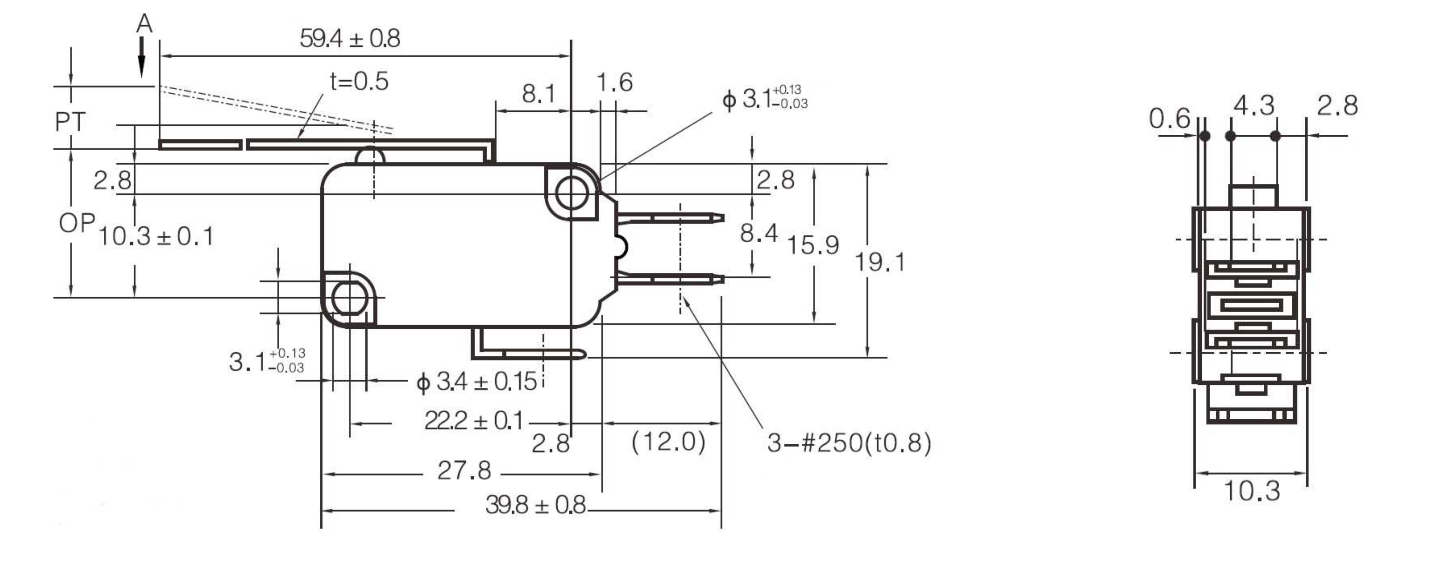

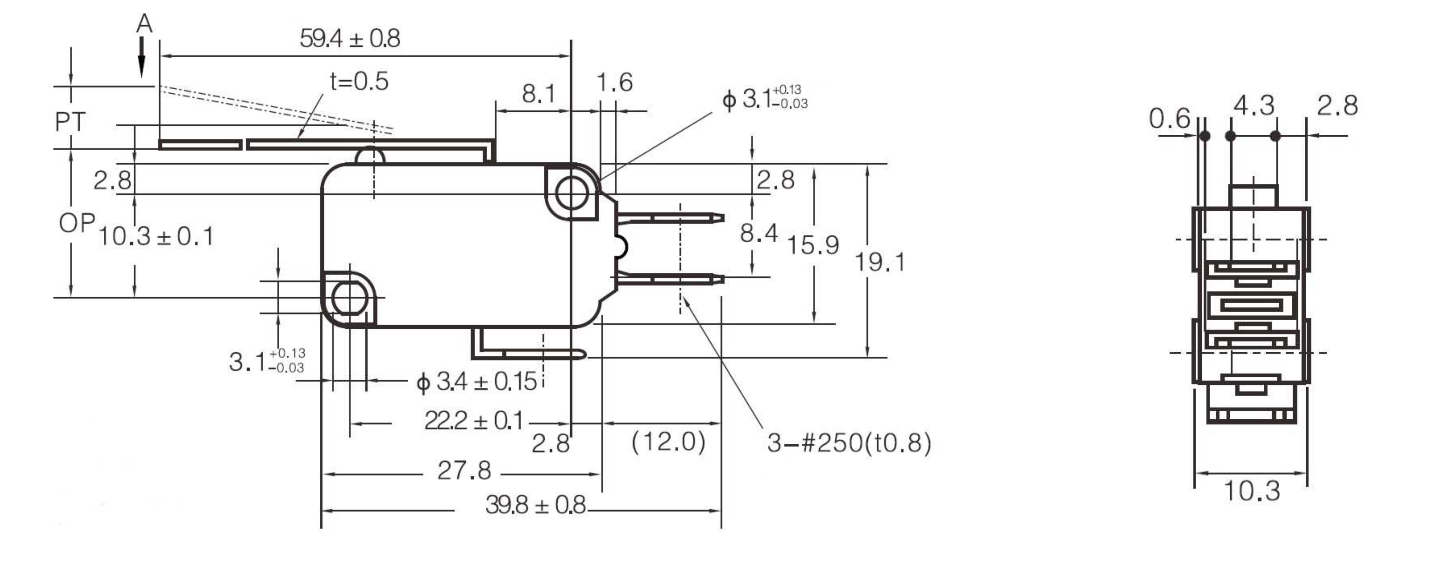

DIMENSIONS (mm)

OPERATING CHARACTERISTICS

Operatingperfomance | NV-21Z2 | NV-16Z2 | |

OF max. | 1.27N | 0.69N | |

RF min. | 0.12N | 0.06N | |

PT max. | 9.0mm | ||

OT min. | 2.0mm | ||

MD max. | 2.8mm | ||

OP | 15.2 -+2.63.2 mm | 15.2±2.6mm | |

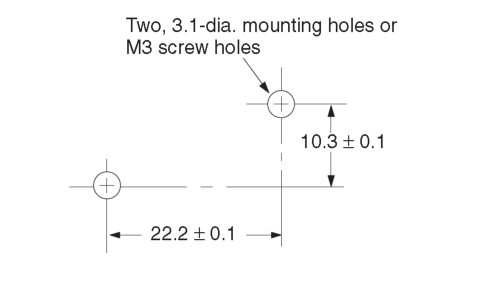

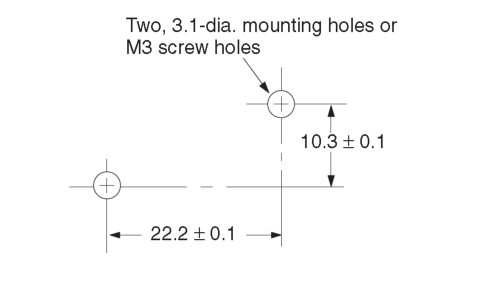

MOUNTING HOLES

All switches may be panel mounted using M3 mounting screws with

plane washers or spring washers to securely mount the switch.

Tighten the screws to a torque of 0.39 to 0.59 N·m.

● Industry standard currents of 16A or 21A

● With long expectancy, reliability

● Variety of levers, terminals and operating forces

● Heat resistant available

● RoHS compliant

ORDERING INFORMATION

NV- □ □ □ □ □ □

① ② ③ ④ ⑤ ⑥

1. Ratings | 2. Contact Gap | 3. Actuator |

21: 21A at 250VAC | None: 1mm | None: Pin plunger |

16: 16A at 250VAC | Z: Hinge lever | |

W: Simulated roller lever | ||

G: Hinge roller lever | ||

4. Contact Form | 5. Terminals | 6. Maximum Operating Force |

None: SPDT | A: Solder terminals | 6: 3.92N |

2: SPST-NC | C: Quick-connect terminal (#250) | 5: 1.96N |

3: SPST-NO | C2: Quick-cinnect terminal (#187) | 4: 0.98N |

RATINGS (REFERENCE VALUES)

Model | Reted voltage | No-inductive load | Inductive load | ||||||

Resistive load | Lamp load | Inductive load | Motor load | ||||||

NC | NO | NC | NO | NC | NO | NC | NO | ||

NV-21 | AC250V | 21A | 3A | 12A | 6A | ||||

DC8V | 21A | 5A | 12A | 7A | |||||

DC30V | 14A | 5A | 12A | 5A | |||||

DC125V | 0.6A | 0.1A | 0.6A | 0.1A | |||||

DC250V | 0.3A | 0.05A | 0.3A | 0.05A | |||||

NV-16 | AC250V | 16A | 2A | 10A | 6A | ||||

DC8V | 16A | 4A | 10A | 7A | |||||

DC30V | 10A | 4A | 10A | 5A | |||||

DC125V | 0.6A | 0.1A | 0.6A | 0.1A | |||||

DC250V | 0.3A | 0.05A | 0.3A | 0.05A | |||||

CONTACT SPECIFICATION

Item Type | NV-21Z2 / NV-16Z2 | ||

Allowable operating speed | 0.1mm~1m/s | ||

Operatingfrequency | Mechanical | 600 times/min | |

Electrical | 30 times/min | ||

Insulation resistance | Min.:100MΩ (above DC500C) | ||

Contact resistance | Max.:30mΩ initial value | ||

Dielectricstrength | BTW same polarity terminals | AC1000V 50/60Hz 1min | |

BTW current-carrying parts | AC1500V 50/60Hz 1min | ||

BTW terminal & metal parts | AC1500V 50/60Hz 1min | ||

Vibrationresistance | Malfunction | 10~55Hz double amplitude 1.5mm | |

Shockresistance | Durable | 1,000 m/s2 (approx. 100G) max. | |

Malfunction | 300 m/s2 (approx. 30G) max | ||

Expected lifelife | Mechanical life | 1x10 6 (60 operations/minute) | |

Electrical life | 1x10 5 (30 operations/minute) | ||

Protection degree | IEC IP40 | ||

Ambient operation temperature | -20℃~+125℃ | ||

Ambient humidity | 60%RH | ||

Contact material | silver alloy | ||

Weight | Approx. 6.2 g (plunger models) | ||

TECHNICAL DATA

Item | NV-21Z2 | NV-16Z2 | ||

Specification | Rivet | |||

Material | Silver alloy | |||

Gap (Standard value) | 0.5mm | |||

Inrushcurrent | NC | 50A max | 40A max | |

NO | ||||

Minimum applicable load | 160mA at 5VDC | |||

CONTACT FORM

TERMINAL

SAFETY APPROVAL

UL61058

CSA-C22.2 No.61058-1

Ratedvoltage | NV-21 | NV-16 |

AC125V | 21A | 16A |

AC250V |

ENEC

(EN61058-1)

Ratedvoltage | NV-21 | NV-16 |

AC125V | 21A | 16A |

AC250V |

CQC

(GB15092.1)

Rated voltage | NV-21 | NV-16 |

AC125V | 21(6)A | 16(4)A |

AC250V |

DIMENSIONS (mm)

OPERATING CHARACTERISTICS

Operatingperfomance | NV-21Z2 | NV-16Z2 | |

OF max. | 1.27N | 0.69N | |

RF min. | 0.12N | 0.06N | |

PT max. | 9.0mm | ||

OT min. | 2.0mm | ||

MD max. | 2.8mm | ||

OP | 15.2 -+2.63.2 mm | 15.2±2.6mm | |

MOUNTING HOLES

All switches may be panel mounted using M3 mounting screws with

plane washers or spring washers to securely mount the switch.

Tighten the screws to a torque of 0.39 to 0.59 N·m.