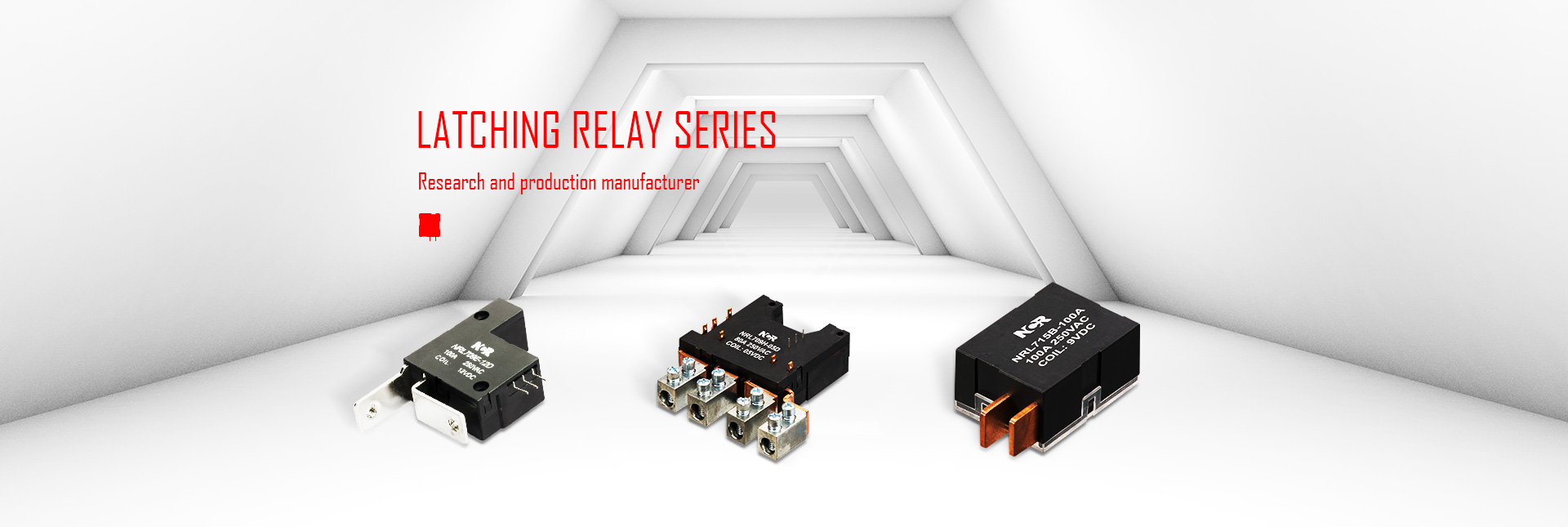

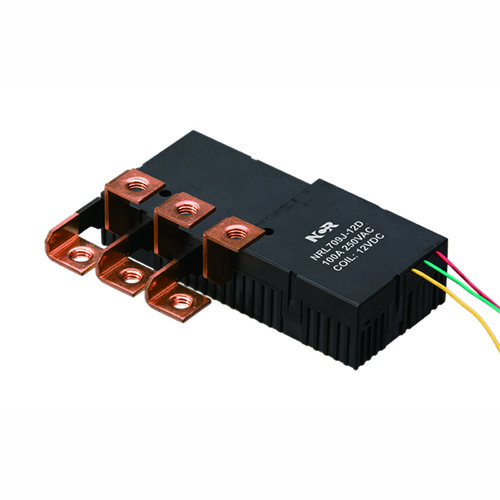

3X100A MAGNETIC LATCHING RELAYS-NRL709J

SOCKETS FOR RELAYS-PYF08A-E2

100A/120A MAGNETIC LATCHING RELAYS-NRL709E

SHUNT-EBW SHUNT-TYPE N2

PCB RELAYS-NRP16

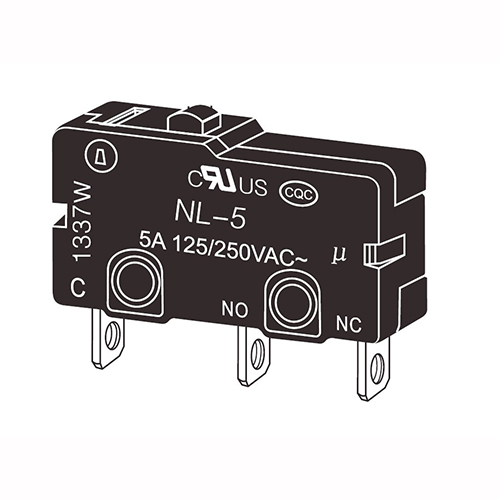

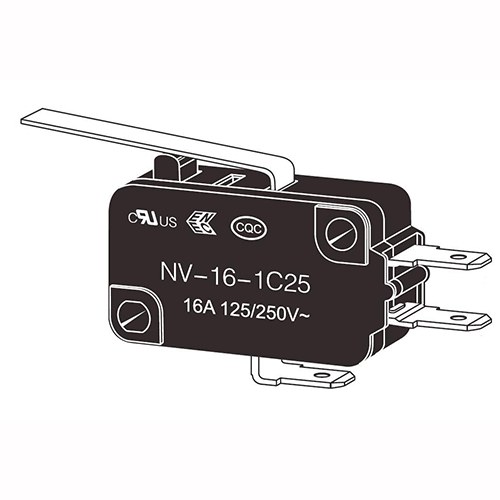

MICRO SWITCHES-NV-21Z

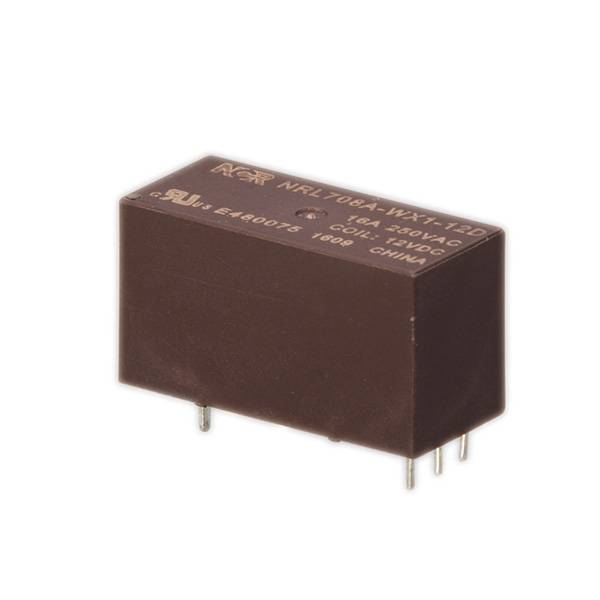

16A/20A MAGNETIC LATCHING RELAYS-NRL708A

PCB RELAYS-NRP10

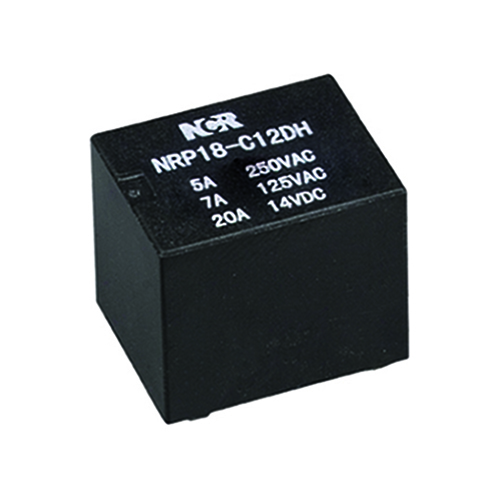

AUTOMOTIVE RELAYS-NRP18

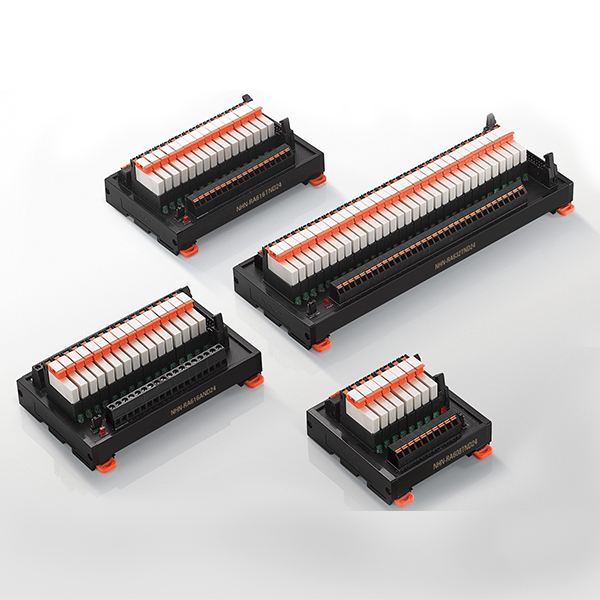

NHN-TTA20&TTA20K&TTA34&TTA34K&TTA40&TTA40K

3X80A MAGNETIC LATCHING RELAYS-NRL709L

SOLID STATE RELAYS-HHG1-0